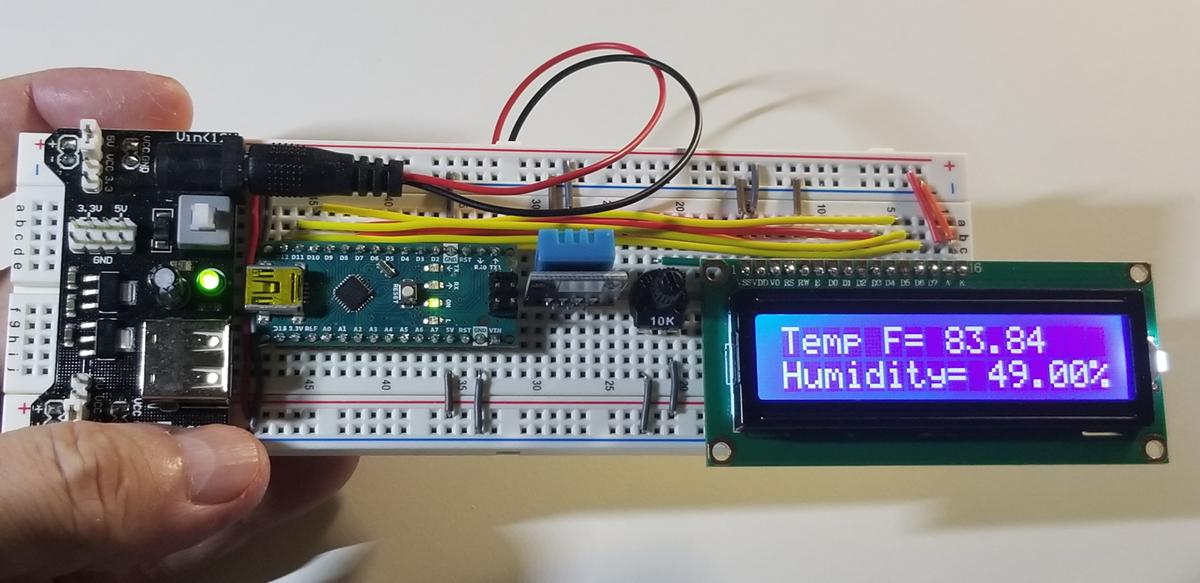

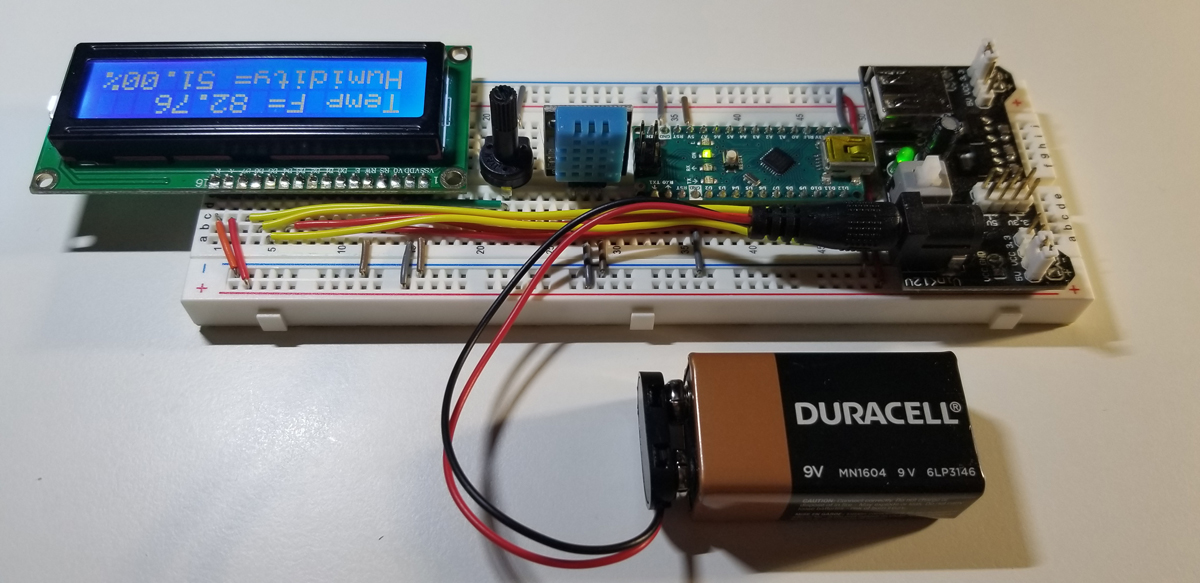

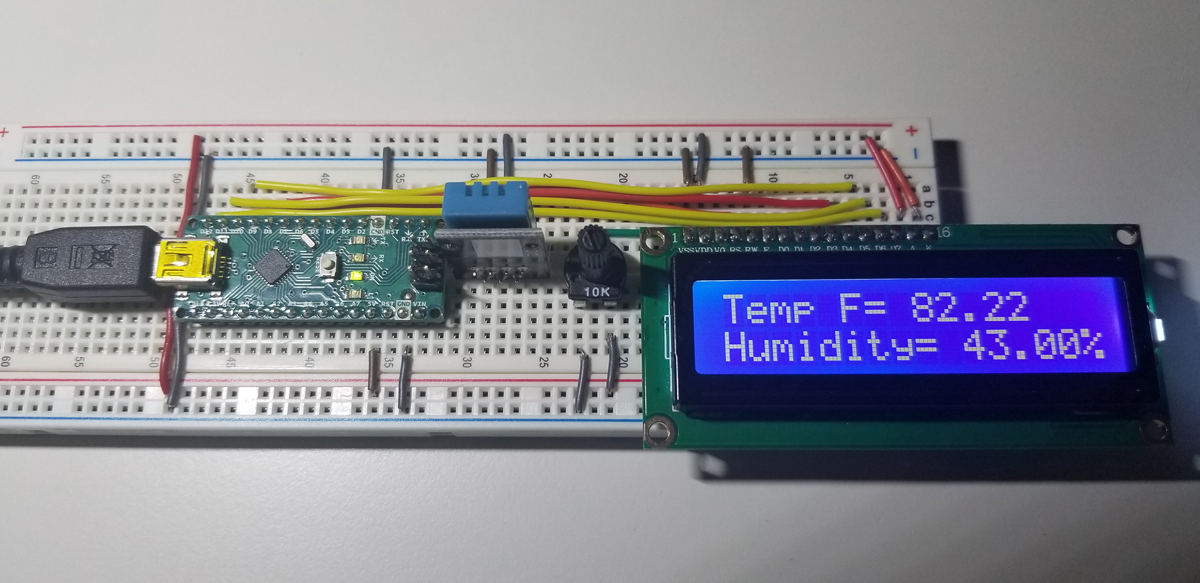

The purpose of this build is to become more familiar with how to develop a free-standing Arduino system using the Arduino Nano. The Nano is a smaller equivalent to the Arduino Uno, but with fewer interface options. It obviously occupies less space since it is a smaller footprint while having reduced overall dimensions. The project makes use of a DHT temperature and humidity sensor that interfaces with the Nano and it includes a 16×2 LCD display to indicate measurement results.

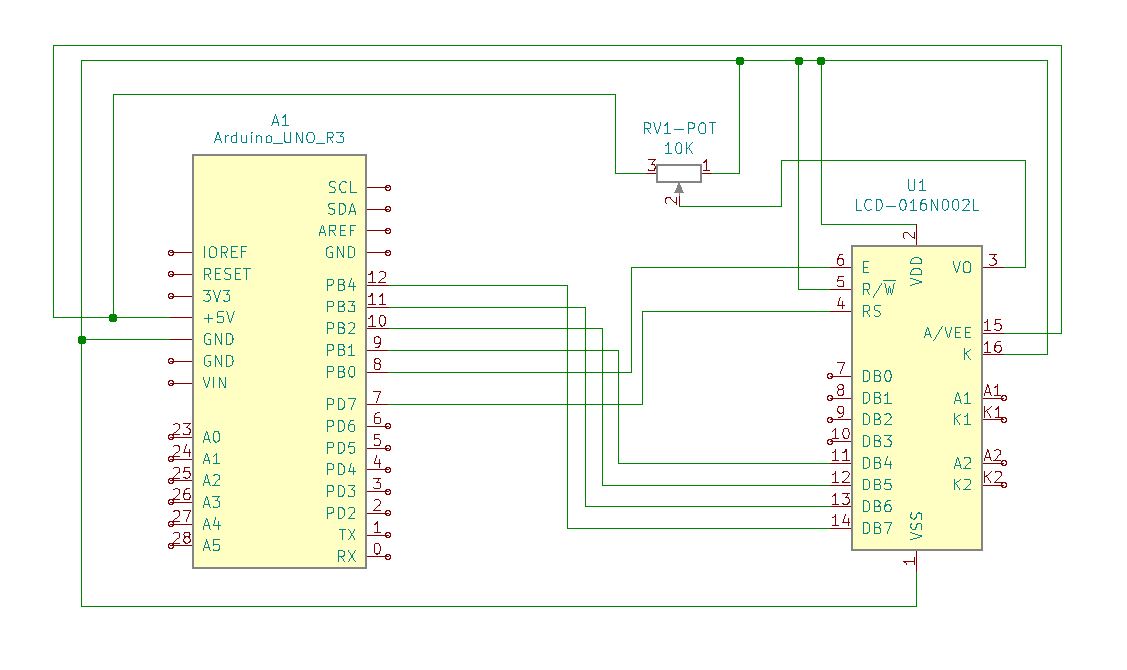

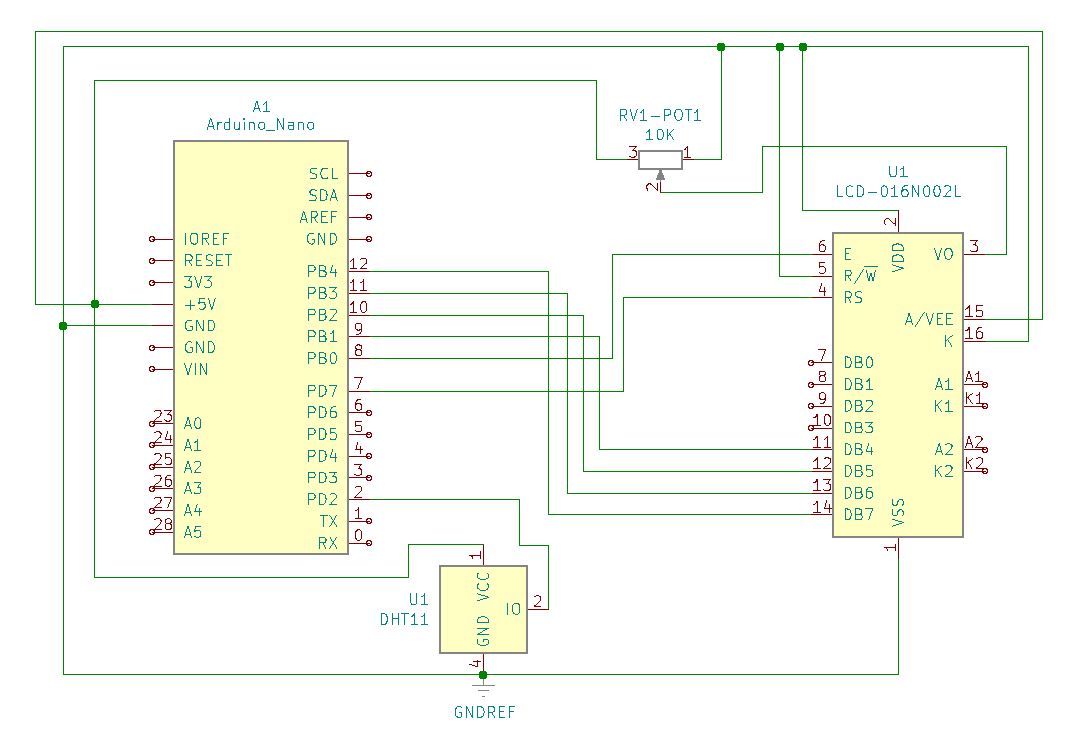

1602A LCD Display Pinout

| Pin | Symbol | Function |

|---|---|---|

| 1 | VSS | Ground |

| 2 | VDD | +5VDC |

| 3 | V0 | Contrast |

| 4 | RS | Register |

| 5 | R/W | Read/Write |

| 6 | E | Enable |

| 7 | D0 | Data |

| 8 | D1 | Data |

| 9 | D2 | Data |

| 10 | D3 | Data |

| 11 | D4 | Data |

| 12 | D5 | Data |

| 13 | D6 | Data |

| 14 | D7 | Data |

| 15 | A | Anode (+5VDC) |

| 16 | K | Cathode (Ground) |

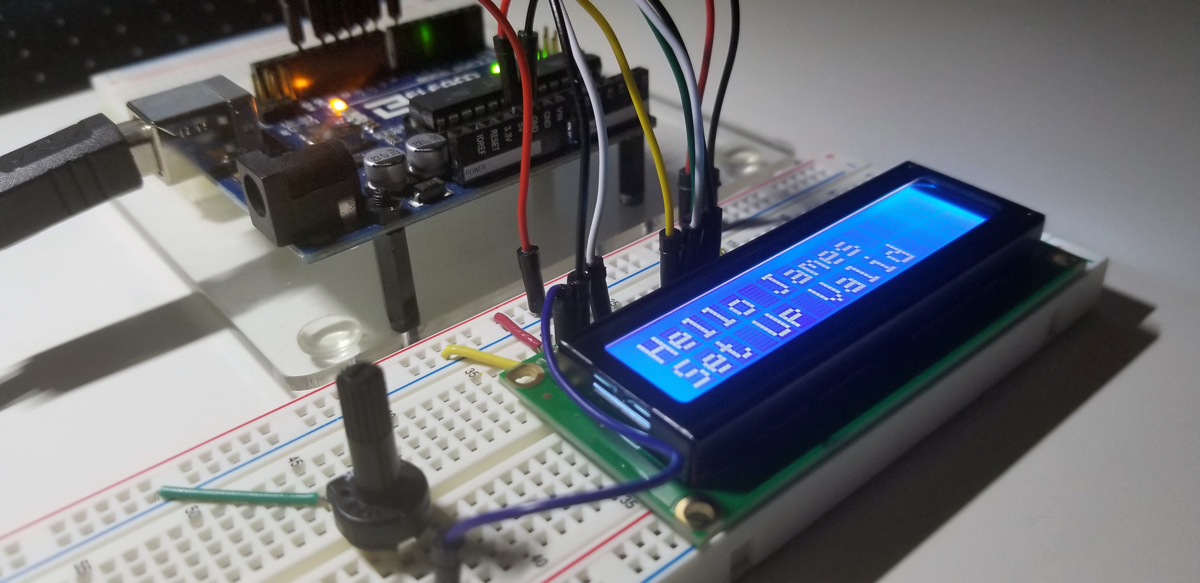

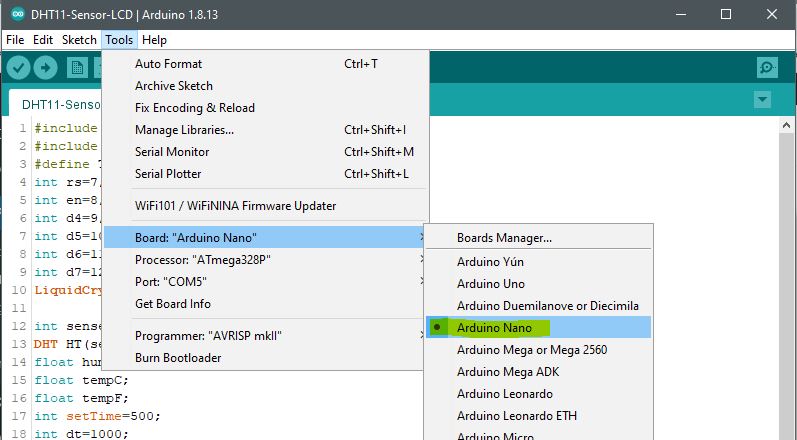

Arduino Setup:

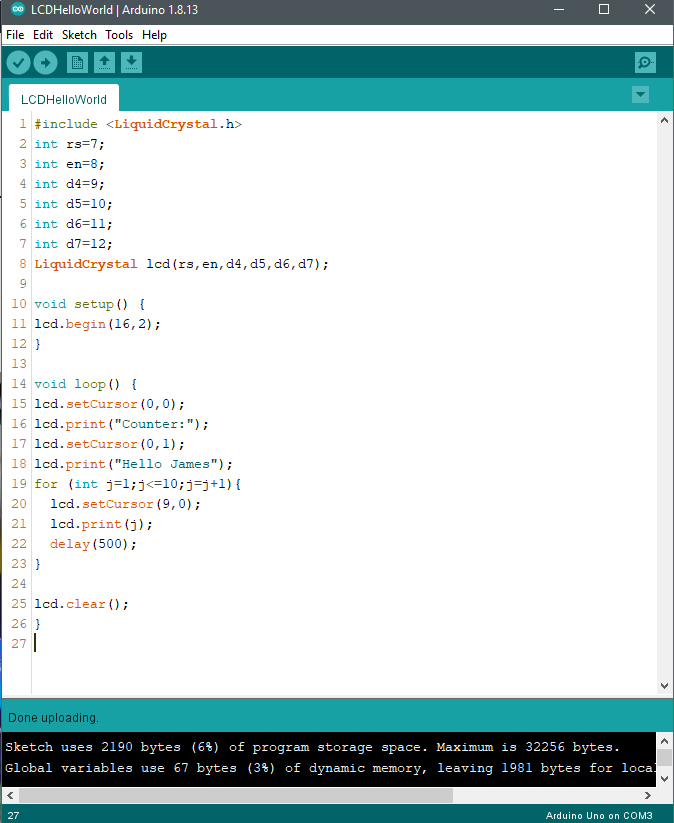

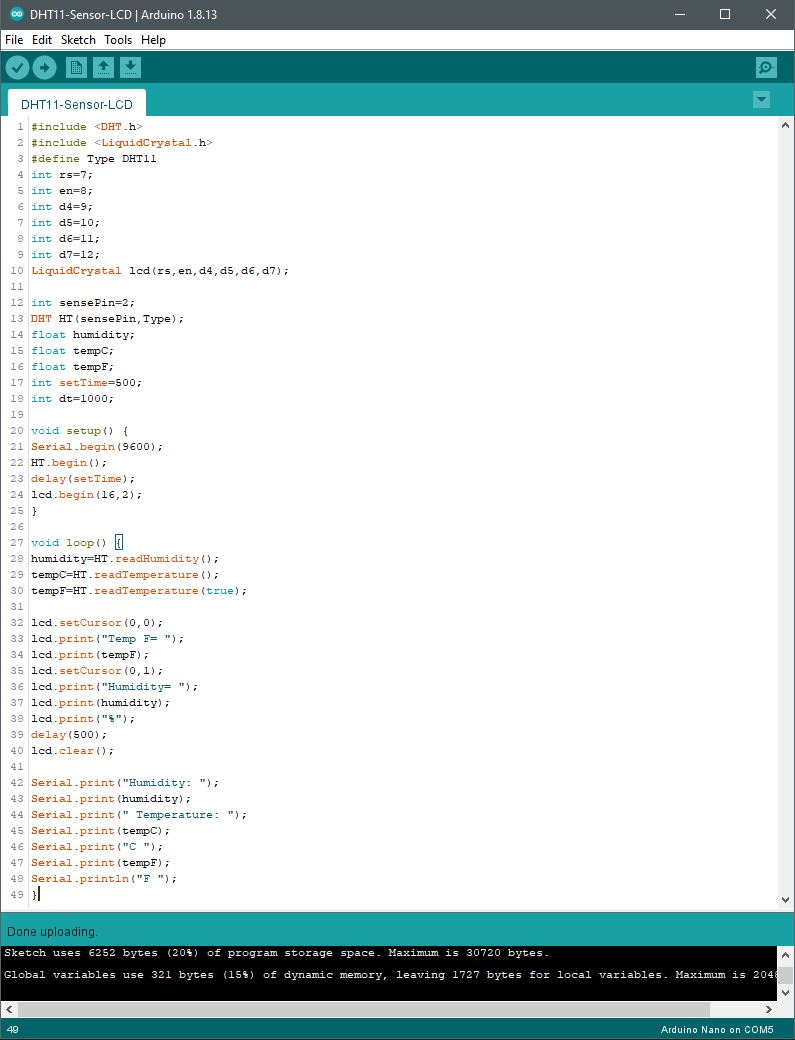

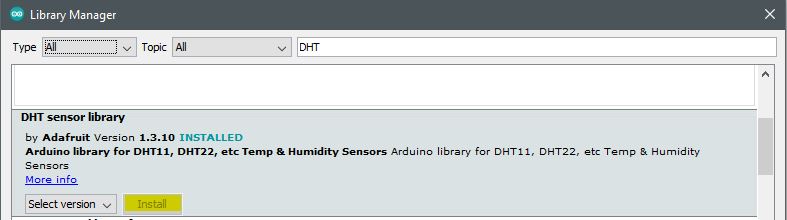

Code Setup:

#include <DHT.h>

#include <LiquidCrystal.h>

int rs=7;

int en=8;

int d4=9;

int d5=10;

int d6=11;

int d7=12;

LiquidCrystal lcd(rs,en,d4,d5,d6,d7);

int sensePin=2;

DHT HT(sensePin,Type);

float humidity;

float tempC;

float tempF;

int setTime=500;

int dt=1000;

void setup() {

Serial.begin(9600);

HT.begin();

delay(setTime);

lcd.begin(16,2);

}

void loop() {

humidity=HT.readHumidity();

tempC=HT.readTemperature();

tempF=HT.readTemperature(true);

lcd.setCursor(0,0);

lcd.print(“Temp F= “);

lcd.print(tempF);

lcd.setCursor(0,1);

lcd.print(“Humidity= “);

lcd.print(humidity);

lcd.print(“%”);

delay(500);

lcd.clear();

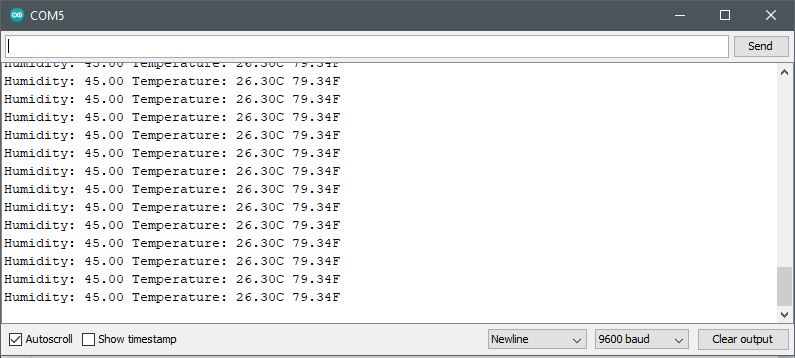

Serial.print(“Humidity: “);

Serial.print(humidity);

Serial.print(” Temperature: “);

Serial.print(tempC);

Serial.print(“C “);

Serial.print(tempF);

Serial.println(“F “);

}